Our Services

3D Printing,3D Scanning/RE & CNC

Filament (FDM)

FDM (Fused Deposition Modeling) is a popular 3D printing technology that uses thermoplastic materials to create parts layer by layer.

Applications:

Prototyping, functional parts, jigs, fixtures.

Materials:

PLA, ABS, PETG, Nylon.

Post-Processing:

Sanding, painting, chemical smoothing.

Design Guidelines:

Minimum wall thickness: 1mm, Layer height: 0.1–0.3mm.

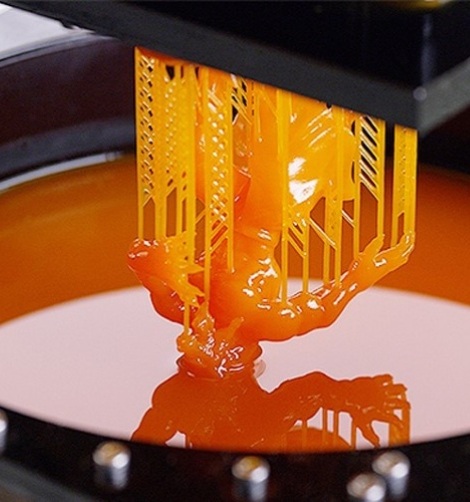

Resins (SLA/DLP/PJP/MJP)

SLA (Stereolithography) uses a laser to cure liquid resin into hardened plastic in a layer-by-layer process.

Applications:

High-detail prototypes, dental models, jewelry, medical, manufacturing.

Materials:

Standard resin, tough resin, flexible resin.

Post-Processing:

UV curing, sanding, painting.

Design Guidelines:

Minimum wall thickness: 0.5mm, Layer height: 0.05–0.1mm.

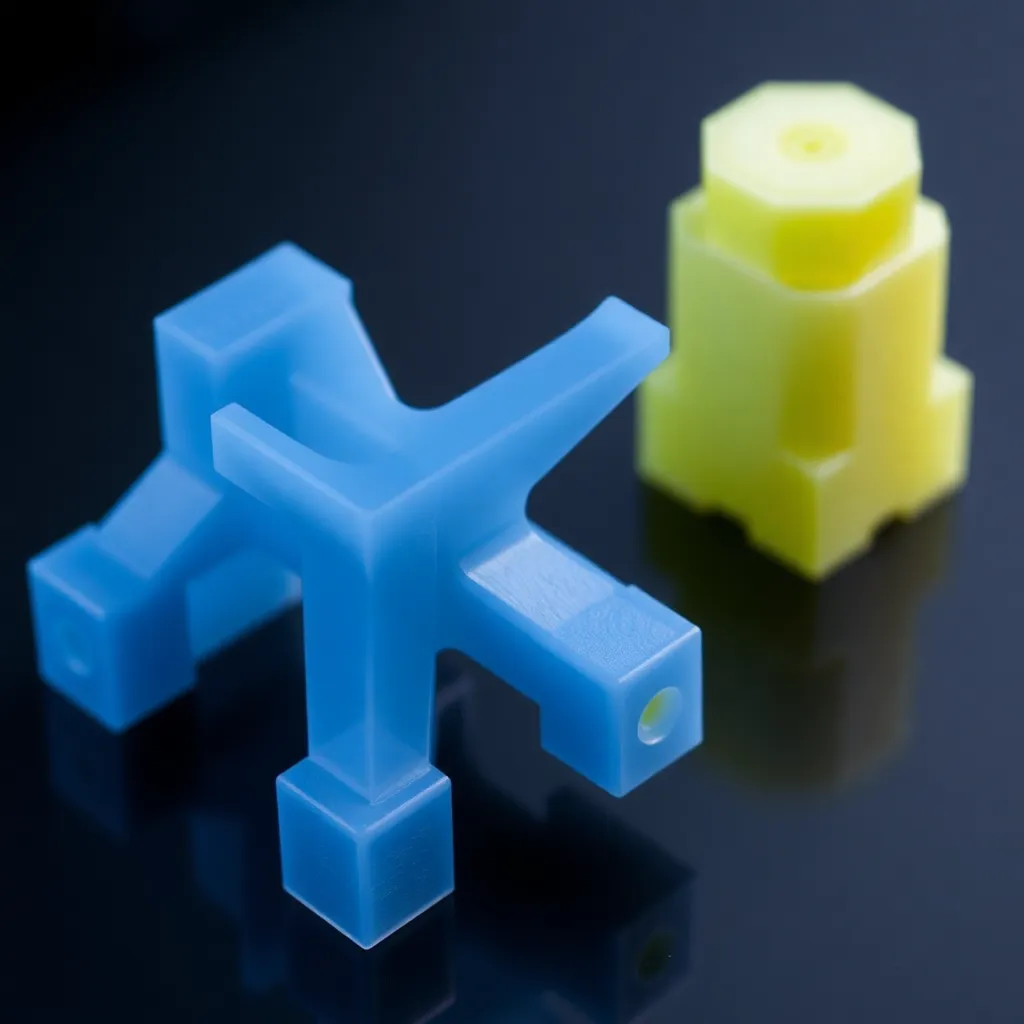

Powders (SLS, MJF)

SLS (Selective Laser Sintering) and MJF (Multi Jet Fusion) use powdered materials to create parts by fusing them layer by layer.

Applications:

Functional prototypes, end-use parts, complex geometries, manufacturing.

Materials:

Nylon, TPU, PA12.

Post-Processing:

Bead blasting, dyeing, painting.

Design Guidelines:

Minimum wall thickness: 0.7mm, Layer height: 0.08–0.12mm.

Metals (DMLS)

DMLS (Direct Metal Laser Sintering) uses a laser to sinter powdered metal into solid parts layer by layer.

Applications:

Functional metal parts, aerospace components, medical implants.

Materials:

Aluminum, Stainless Steel, Titanium, Inconel.

Post-Processing:

Heat treatment, machining, polishing.

Design Guidelines:

Minimum wall thickness: 0.5mm, Layer height: 0.02–0.05mm.

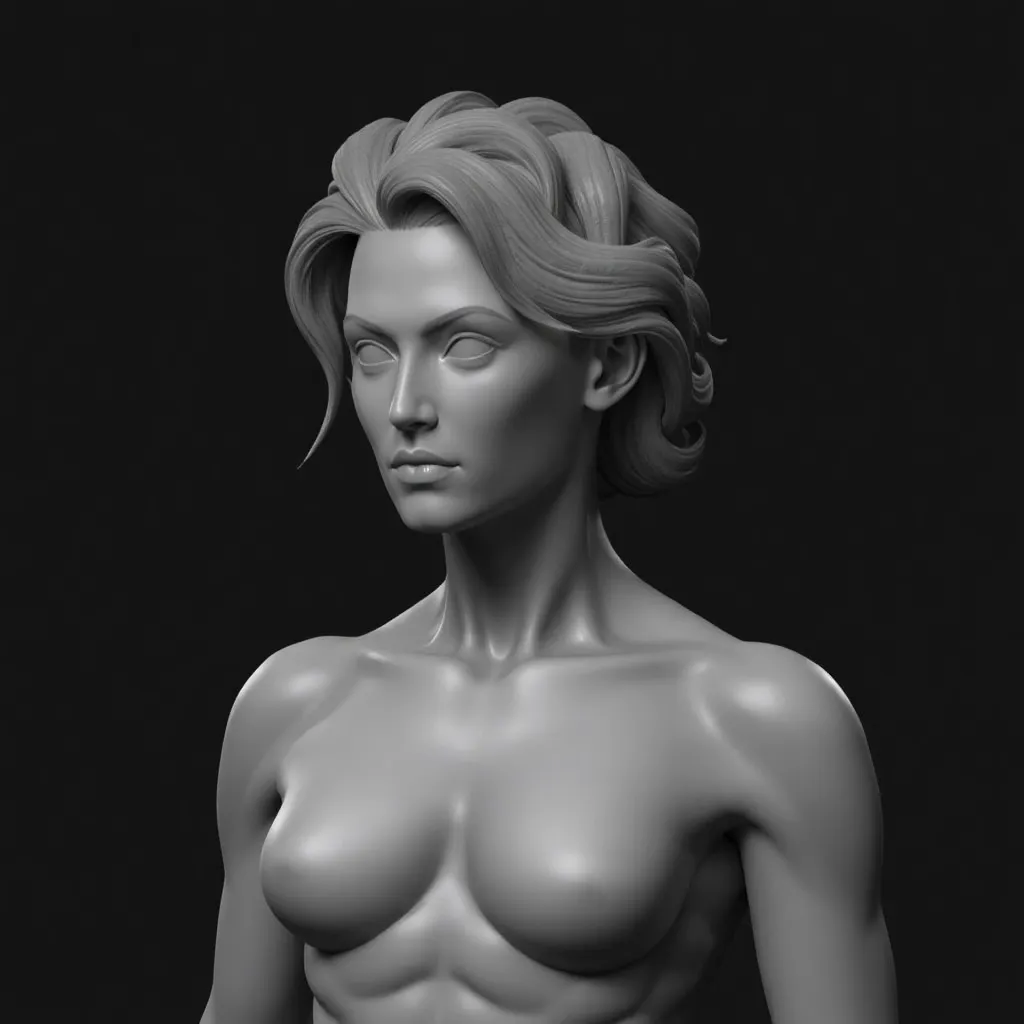

Digital Sculpting

Digital sculpting tools provide the power and flexibility required in several stages of the digital production pipeline.

Applications:

Character design, product design, art creation.

Output:

Digital files, 3D models..

Post-Processing:

3D printing, rendering, animation.

Final Output:

High-resolution models, detailed textures.

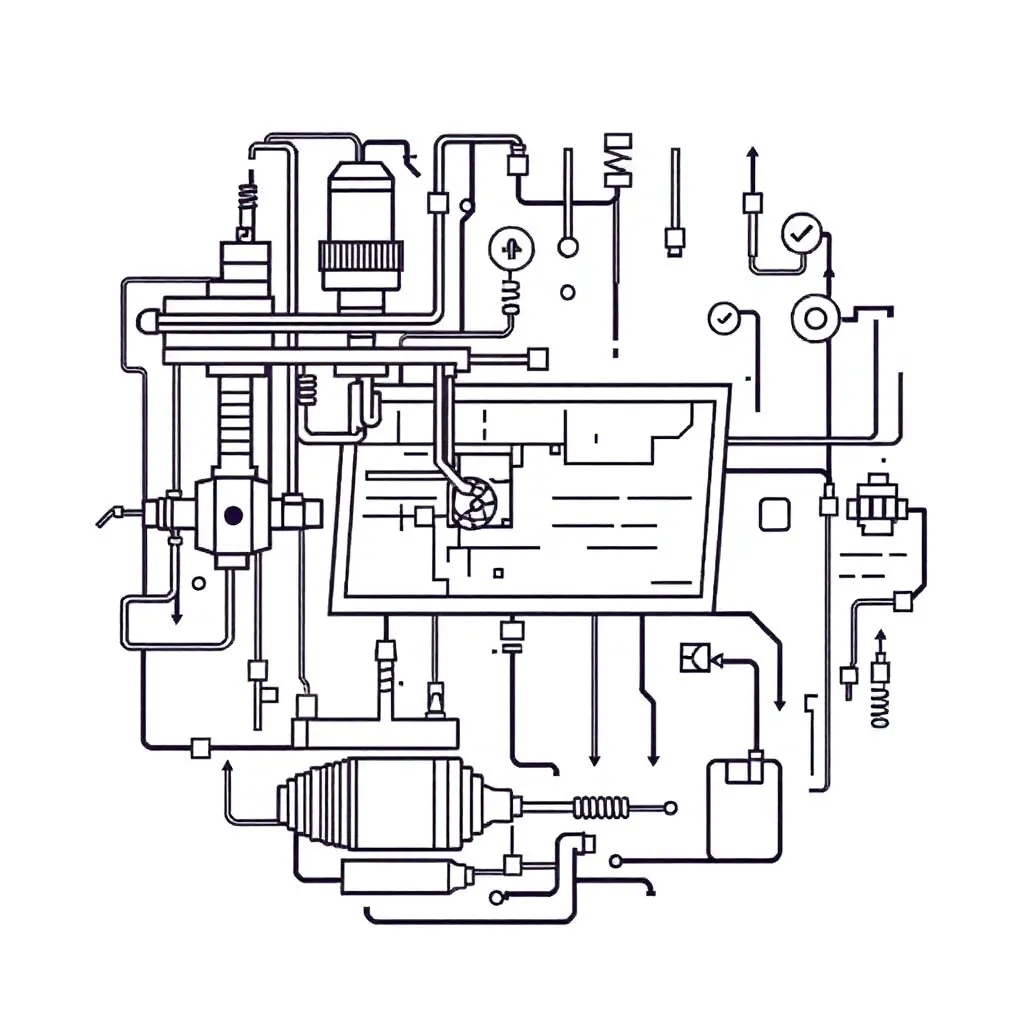

Reverse Engineering

Recreation of 3D scan data into CAD models enabling analysis, optimization, and remanufacture of parts and assemblies.

Applications:

Part replication, design optimization, quality control.

Output:

3D scan data, CAD models.

Post-Processing:

CAD modeling, 3D printing, CNC machining.

Design Guidelines:

Accurate measurements, detailed scans.

Dimension Inspection

3D measurement data from scanners and PCMMs offers a comprehensive definition of a physical object for measurement, inspection, comparison, and reporting.

Applications:

Quality control, part verification, dimensional analysis.

Materials:

3D scan data, physical parts.

Post-Processing:

Inspection reports, CAD comparison.

Design Guidelines:

High-accuracy scans, detailed measurements.

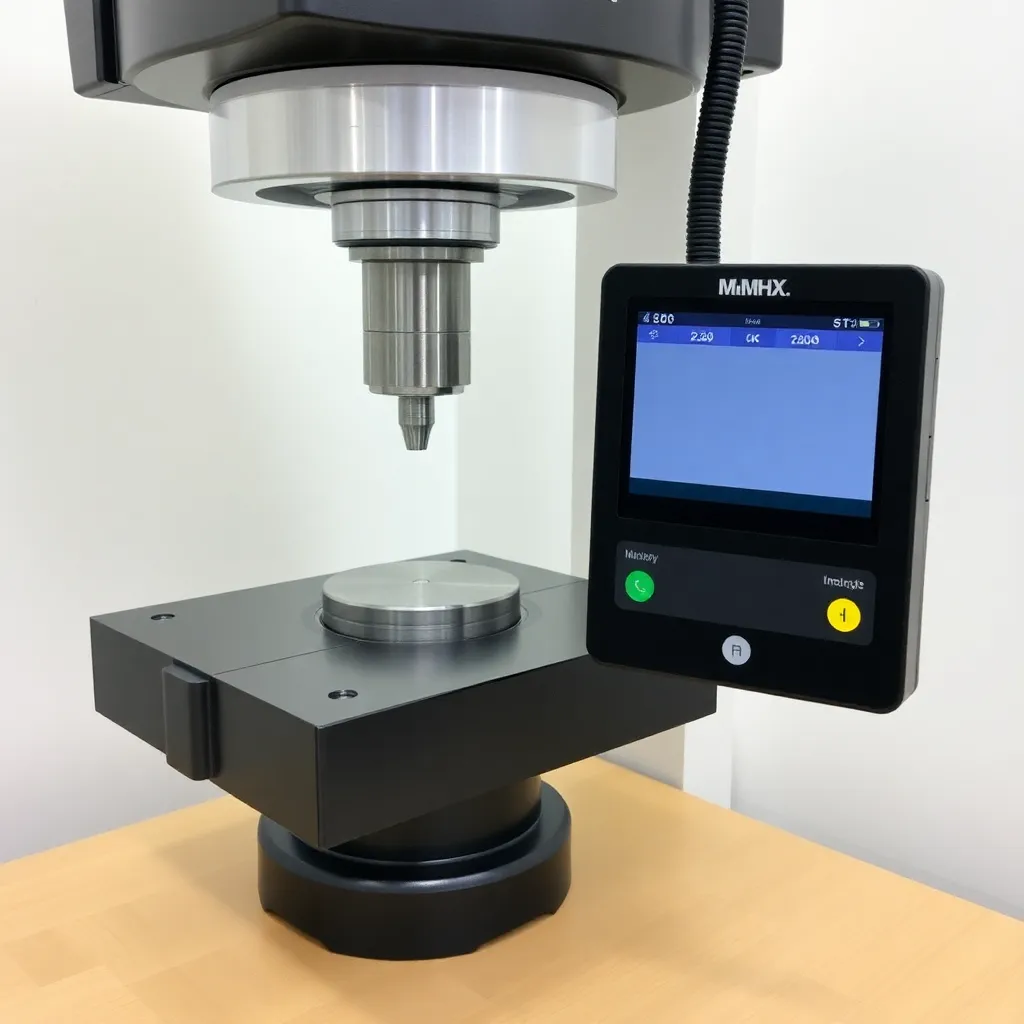

CMM Measurements

Portable measuring CMM arms allow you to measure on the machine or shop floor with no homing procedures, simplicity of operation, and reliable 3D measurements.

Applications:

On-site measurements, quality control, part verification.

Materials:

Physical parts, 3D scan data.

Post-Processing:

Inspection reports, CAD comparison.

Design Guidelines:

High-accuracy measurements, detailed scans.

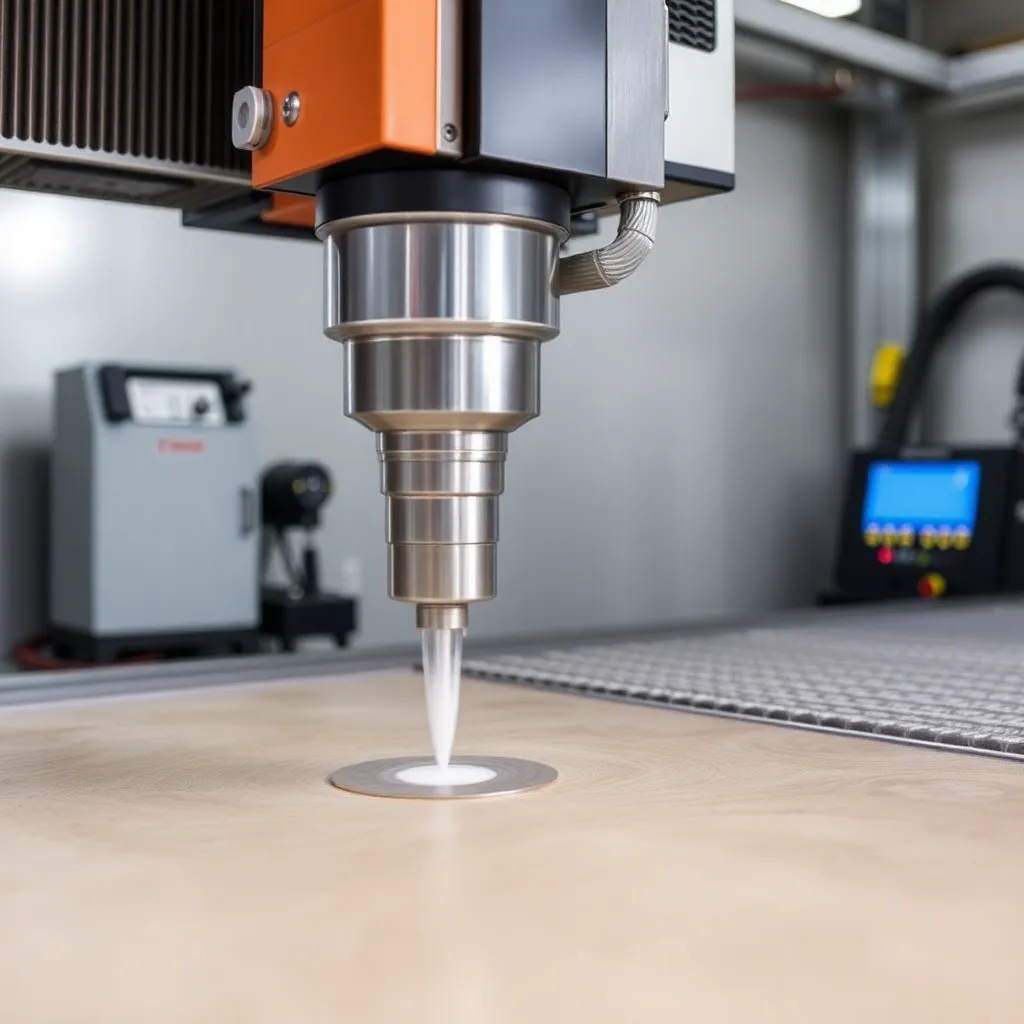

CNC Milling

CNC milling process produces custom prototypes and end-use production parts using 3-axis milling machines.

Applications:

FPrototyping, production parts, complex geometries.

Materials:

Aluminum, steel, plastics, composites.

Post-Processing:

Surface finishing, anodizing, painting.

Design Guidelines:

Minimum wall thickness: 0.5mm, Tolerances: ±0.1mm.

CNC Turning

CNC turning is an intricate and detailed method of creating components using a lathe.

Applications:

Round parts, shafts, bushings.

Materials:

Aluminum, brass, steel, plastics

Post-Processing:

Surface finishing, anodizing, painting.

Design Guidelines:

Minimum wall thickness: 0.5mm, Tolerances: ±0.1mm.p>

CNC 5-Axis

5-axis machining allows high-precision machining of complex parts that is far beyond what other techniques can provide.

Applications:

Complex geometries, aerospace components, medical devices.

Materials:

Aluminum, titanium, steel, plastics.

Post-Processing:

Surface finishing, anodizing, painting.

Design Guidelines:

Minimum wall thickness: 0.5mm, Tolerances: ±0.05mm.

CNC Turn Mill

CNC Turn Mill machines combine the capabilities of turning and milling in a single setup, providing efficient and precise manufacturing.

Applications:

Complex parts, multi-functional components, high-precision parts.

Materials:

Aluminum, steel, brass, plastics.

Post-Processing:

Surface finishing, anodizing, painting.

Design Guidelines:

Minimum wall thickness: 0.5mm, Tolerances: ±0.05mm.